CB2000 WEARPLATE

CB2000 wearplate provides the

ultimate in cost-effective abrasion Resistance. It's duplex structure of high

quality mild steel as a substrate overlaid with a proprietary alloys of

chromium, carbon, manganese, and iron. This unique alloys combined with a

controlled state-of-the-art manufacturing process results in an overlay

undiluted by base material (substrate) consisting of massive quantities of

chromium carbides in a matrix of hard martensite combined with enough retained

austenite to make the plate readily formed.

This combination of wear resistance

and formability make CB2000 the cost-effective solution to your abrasive

wear problems. CB2000 can be easily formed and welded into complex or

simple engineered components and can be weld repaired in the field. CB2000

wearplate is manufactured under strict quality controlled systems approved to

ISO 9002 quality standards.

CB2000 overlaid plate is used in many segments of

industry:

·

Steelworks

·

Mining

·

Refineries

·

Cement

·

Glass

·

Timber

·

Power Plants

·

Earthmoving

GENERAL DESCRIPTION

The CB2000 overlay alloy for steel plate has

been developed for applications requiring high resistance against wear by

abrasion combined with moderate to low impact.

TYPICAL PROPERTIES

OF UNDILUTED CB2000 ALLOY

The properties given directly below refer

only to the CB2000 alloy, undiluted by base material substrate). These

properties differ from the properties of actual overlay deposits on a particular

substrate, examples of which are given in the next section.

|

Type of Alloy |

Iron based |

|

Group of Alloys |

High chromium iron |

|

Nominal composition |

4.0-5.0 % C, 2.0-3.0% Mn, 42%-48% /Cr

|

|

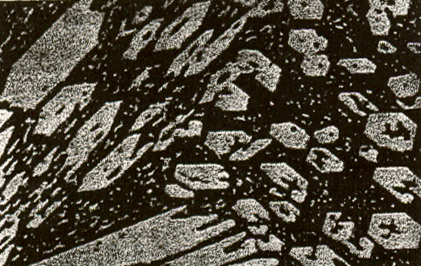

Microstructure |

Hyper-Eutectic with MC primary

chromium carbides in an austenitic eutectic Matrix |

|

Typical hardness range |

62-64 Rc |

|

Cracking |

Yes |

|

Abrasion Resistance |

Excellent |

|

Impact Resistance |

Moderate |

|

Typical service

temperature |

Up to 650 C ° (1,200

F) |

|

Machining |

Only grinding |

|

Flame cutting |

No, only with plasma or cutting

electrode |

|

| |

Standard Base plate grades

In the USA: ASTM A-36

In the UK: BSEN 10025: 1993 Fe 430A (BS 4360-43A)

(The image above is a typical microstructure)

CARIBEL CB2000 WEARPLATE

SPECIFICATIONS

|

PART NO. |

THICKNESS |

SIZE |

WEIGHT |

WT./SQ.FT. |

|

4555 |

1" (.5" on

.5") |

60" x

120" |

2040 lbs. |

40.8

lbs. |

|

4343 |

¾ (.375 on

.375) |

60" x

120" |

1530 lbs. |

30.6

lbs. |

|

4444 |

½" (.250 on

.250) |

60" x

120" |

1020 lbs. |

20.4

lbs. |

|

4242 |

3/8"(.125 on

.250) |

60" x

120" |

765 lbs. |

15.3

lbs. |

|

( All of the above sizes

include 2 (two) pases of chrome carbide)

| ||||

«back